|

|

|

OPERA - OPTIMISATION OF OF THE TIMBER SUPPLY CHAIN Mareike Schultze, M. Lange, Herbert Sonntag ABSTRACT The cooperative project "Sustainable Management of Mixed Oak-Pine-Forest Stands in the Sub continental North-eastern German Lowlands (Oak Chain)" estimates technical, economical and ecological aspects of Mixes Oak-Chain-Forest Stands. The conversion of pine monocultures into mixed oak and pine stands entails an adaptation of the entire wood supply chain. The sub-project OPERA, which is managed by TFH Wildau, develops new methods for the transport logistics from forest to production site. Key aspects of activity are the navigation and positioning with RFID-technology and the optimization of the transport organization and the flow of information. INTRODUCTION The forest-based sector is an important economic factor in Germany and particularly in the economically underdeveloped regions of Brandenburg. The cooperative project of the Federal German Ministry of Education and Research "Oak-Chain - Sustainable Management of Mixed Oak-Pine-Forest Stands in the Sub-Continental North-Eastern German Lowlands" investigates new strategies for the conversion of pure pine stands into mixed oak-pine-forest stands. The focal points in this project are silvicultural, economic and environmental aspects of mixed oak-pine stands, the usage of small-dimensioned oak timber and the optimization of the timber value chain. The conversion of pine monocultures into mixed oak and pine stands entails an adaptation of the entire timber supply chain. The challenge is twofold: on the one hand, the market conditions for small-dimensioned oak logs are very poor. Sophisticated logistics concepts are needed to allow for a higher added value. On the other hand, wood procurement costs are likely to rise due to assortment diversification. Timber allocation and transport costs have a share of up to 80% of the overall procurement costs. They are decisive for the profitability of the entire value chain. The logistical subproject OPERA "Optimization between pile and ramp" focuses therefore upon the transport chain for small-dimensioned pine and oak logs from wood road to production site. Optimized timber transport chains link sustainable forest management to economically sound timber utilization. This paper shall deliver insight into the issue of timber transport logistics and provide an out-look on the research activities in the OPERA project. The center of interest is the transport chain for timber procurement from forest to production site. To begin with, some background information on the current status of the forest-sector is given and current challenges with respect to logistics are outlined. Then, an analysis of the timber transport chain is presented. Weak points and areas where there is room for improvement in timber transport chains in Brandenburg are identified. Finally, solutions in terms of transport logistics suggested within the framework of the OPERA project are sketched out. THE CURRENT SITUATION OF THE FOREST-BASED SECTOR IN BRANDENBURG In the federal state of Brandenburg, the forest and timber industry is an important employer with over 6500 persons working in the public forest service, in forest enterprises, logging companies and in the wood processing industry. Its annual turnover of over 800 million euros shows the economic importance of this sector [MLUV, 2004]. The conditions for the German forest and timber industry have altered considerably over the last decades. There are novel requirements to forest operations coming from economic, ecological and structural changes [Becker et al, 2002, 2005; Strunk, 2003]. Key factors affecting the forest-sector in Brandenburg are:

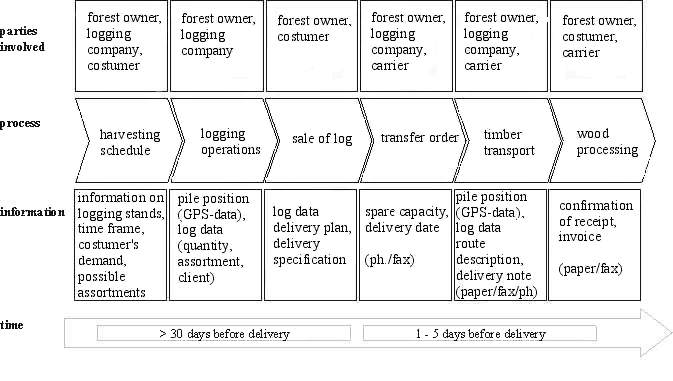

To speed up operational processes in the timber supply chain, new systems and technologies are needed. Novel timber harvesting and supply technologies are, thus, an important field of research. In timber harvesting a high level of mechanization has already been achieved [Becker et al., 2002; Ehrhardt, 2005]. Further rooms for improvement come from the reorganization of timber transportation processes. Since logistics is an important cost factor, efficient transport chains are crucial for the profitability of the entire value chain. Research activities in the OPERA project focus therefore on the transport chain for timber procurement from the pile at the wood road to the industrial production site. Key factors for significantly reducing costs and time of timber transportation are the effective transport organization, the use of modern information and communication technology and novel solutions for navigation and position in the forests. POTENTIALS FOR OPTIMISATION OF THE TIMBER SUPPLY CHAIN The timber supply chain consists of the processes necessary to deliver timber from the pile in the forest to the ramp at the production site including organizational and operational processes as well as flows of information between the parties involved. Numerous partners characterize the traditional timber transport chain. Interfaces between the single processes are often undefined and information flows are incomplete, discontinuous and very slow. The responsibility for transport planning and organization can be assumed by different partners according to the specific situation. Either the costumer (delivery to wood road) or by the forest owner and the logging company (delivery to production site) respectively are responsible for transport planning and organization and for choosing and instructing the carrier. The transport to the production site is performed by carriers, mostly small and medium enterprises (SME) who often are associated to the logging companies or act as their subcontractors. They dispose of special equipment for the handling and transportation of round wood, for instance lorries with integrated cranes and adapted under-carriages.

The business processes of timber transport are still organized in a very traditional way and there is much room for improvement. The use of communication and information technologies is not very common. Information is usually forwarded by telephone or fax. Continuous end-to-end flows of information between the partners of a supply chain are scarce. An optimization of flow of information and transport planning procedures is therefore likely to raise significantly the efficiency of transportation processes.

Transport Planning and Organisation Cost and time efficient transportation depends on effective transport planning methods. Transport planners using fleet optimization techniques are able to combine transfer orders in an optimized way and, by this, to increase the performance of their fleet. As a result, the share of dead ends and unproductive periods can be reduced and overall costs can be trimmed down. However, the software tools currently available for transport planning are very expensive and they are not adapted to the special requirement of timber transport. There is a lack of reasonably priced software tools that can be used as a support for transport planning and fleet optimization in the field of wood procurement. Most small and medium sized timber carriers are therefore not able to plan efficiently their operations to optimize their resource exploitation. Exchange of information and data transfer Another reason for the low efficiency of timber transport operations are slow information flows and insufficient data exchange between partners. For high logistical performances in their transport operations, wood carriers need a data basis for transport planning in sufficient time before the delivery date. However, since forest enterprises and wood owners are usually not able to warrant timely information flows, carriers often act on very short notice. A concerted effort by all partners in timber supply chains is necessary to improve this situation. Various projects have been launched to create continuous and timely information flows between partners in the forest sector. In a first step, the awareness for this subject has been raised. Considerable effort is currently dedicated to the application of modern technologies in the forest sector to support communication and data exchange between partners. In pilot projects, information platforms for the cross-company communication between partners of timber supply chains have been implemented and model processes have been designed. Special communication tools for the forest sector are for instance GeoMail® and LUKAS®. In Brandenburg, there is currently no system available to support the management of information flows between small and medium sized enterprises in the forest sector such as logging companies, wood carriers, sawmills and private forest owners. Navigation and positioning in the woods Another reason for high transportation costs is the large amount of time dedicated by the wood carriers in finding timber piles in the woods [Rösler, 1999]. This waste of time is mainly due to the following facts:

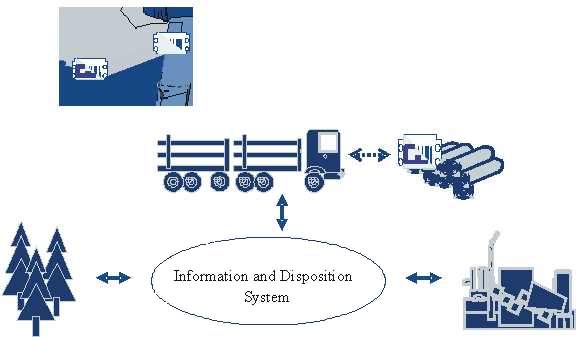

Particularly in the private owned forest, where wood roads are usually in a bad condition, tools for navigation and pile position should be combined with exact route descriptions to save time for localizing the pile. For this purpose, inexpensive and reliable systems for navigation and for pile positioning are needed. RESEARCH ACTIVITIES IN THE OPERA PROJECT The aim of the OPERA project is to provide logistical tools and techniques to partners in timber supply chains so that they can deal with the weak points identified in the paragraphs above. In order to improve the performance and efficiency of timber transport chains, the research program includes three different approaches:

Within the framework of OPERA, software solutions will be developed, customized and implemented in select transport chains. In pilot projects they will be tested in small and medium sized enterprises of the forest-sector in Brandenburg. In detail, the following improvements shall be attained:

Expected outcomes are a generally enhanced performance of the timber transport chain and a significant reduction of deadheads and unproductive periods. Resulting from this, the profitability of timber transportation particularly for small and medium sized enterprises will be increased. The above-mentioned data, tools and techniques for transport planning and optimization will be made available to partners of timber supply chains on a web-based information platform. The platform consists of the following modules:

Additionally an inexpensive and reliable system for navigation in the forest and for pile positioning adapted to the needs of SME timber supply chain in Brandenburg is under development. This system should help carriers to reduce considerably the time needed for localizing woodpiles. For this purpose, the RFID-technology is tested for its performance in low distance positioning and data transfer in outdoor conditions. RFID tags complement the route description and help carriers to localize the exact position of their lorries and of the woodpiles. Additionally, RFID can be used for pile identification and data exchange all along the timber transport chain. Research on similar approaches is going on at the Universities of Munich and Dortmund who are testing the applicability of RFID-technology for data transfer in the timber supply chain [Korten et. al., 2005]. In order to develop solutions adapted to real businesses in the forest-sector, the TFH Wildau cooperates closely with small and medium sized forest enterprises in Brandenburg. In pilot projects the tools will be implemented in select timber transport chains. The work packages are:

CONCLUSION Before the background of major economic, ecological and structural changes in the forest-based sector, cost efficient timber transport changes are needed. Furthermore, the planned conversion of pure pine stands into mixed stands in Brandenburg entails an adaptation of the entire value chain. Innovative and reasonably priced tools are needed to support partners of the timber transport chain in their activities. The project OPERA provides solutions adapted to the needs of small and medium-sized companies of the forest-based sector in Brandenburg. The information and disposition system shall support private forest owners, forest enterprises, wood carriers and their costumers so that they are able to create added value and to optimize their business processes. An up-to date virtual market place for freight shall help to reduce deadheads and unproductive periods. In addition, business processes will become more transparent and straightforward. The RFID-based navigation and position system shall support wood carriers to cut back on unproductive times in the forest by localizing woodpiles in a more efficient way. To assure the applicability and the practical relevance of the developed solutions the University of Applied Science cooperates closely with practitioners from the forest-sector in Brandenburg as well as with several research-labs. REFERENCES Bodelschwingh E. v., Bauer J., Longo M., 2003, Informationsflüsse in der modernen Holzerntekette. AFZ, Der Wald 17/2003, Stuttgart, 855- 857. Ehrhardt I., 2005, Integrierte Holzlogistikkette vom Wald zum Werk - Holzdemonstrator Sachsen-Anhalt. information paper, IFF Fraunhofer, Magdeburg. Forstware Informationssysteme GMBH, 2005, GeoMail - Von der Inventur bis ins Werk. Product information,. GeoMail, Meersburg. Jönsson A., 2005, Der gläserne Wald. Forst und Technik, DLV Verlag München, 6-8. Korten S. et al. 2005, RFID-Technologie in der Holzerntekette, AFZ, Der Wald 18/2005, Stuttgart, 969-970. Landesbetrieb Wald und Holz Nordrhein-Westfalen, 2005, Logistikkette Holz NRW Informationsbroschüre LIGNA 2005, Münster. Ministerium für Ländliche Entwicklung und Verbraucherschutz (MLUV) des Landes Bran-denburg, 2004, Cluster Forst und Holz in Brandenburg. Stand und Perspektiven, Referat Presse und Öffentlichkeitsarbeit des MLUV-Brandenburg, Potsdam. Rösler S., 1999, Die optimale Logistikkette: Wie können Holztransport und Holzhandel besser in die Logistikkette integriert werden, Forsttechnische Informationen 10, Groß-Umstadt. Strunk M, 2003, Zum Einsatz von Wechselbrücken beim Rohholztransport in der deutschen Forst- und Holzwirtschaft, Institut für Forstliche Arbeitswissenschaft und Verfahrenstechnologie der Universität Göttingen. OPERA - OPTYMALIZACJA £AÑCUCHA DOSTAW DREWNA

STRESZCZENIE Przedmiotem badañ w projekcie "Zagospodarowanie le¶nych siedlisk mieszanych dêbowo-sosnowych na obszarze pó³nocno-wschodnich Niemiec" s± techniczne, ekonomiczne i ekologiczne aspekty przekszta³cenia tych stanowisk. Konwersja monokultury sosnowej w mieszane zalesienia dêbowo-sosnowe wymusza zmianê ca³ego ³añcucha dostaw drewna. Projekt OPERA, realizowany przez Wy¿sz± Szko³e Techniczn± w Wildau, ma na celu opracowanie nowych rozwi±zañ logistycznych transportu drewna ze stanowisk w lesie do przetwórni. Kluczowymi aspektami s±: sposób nawigacji i pozycjonowania przy zastosowaniu technologii RFID, optymalizacja transportu i przep³ywu informacji. OPERA - OPTIMIERUNG DER HOLZ-LIEFERKETTE

ZUSAMMENFASSUNG. Das Verbundprojekt "Nachhaltige Bewirtschaftung von Eichen-Kiefern-Mischbeständen im subkontinentalen Nordostdeutschen Tiefland" untersucht wald-bauliche, technische, ökologische und betriebswirtschaftliche Aspekte von Eichen-Kiefern-Mischbeständen. Der Umbau von Kiefernmonokulturen in Mischwälder stellt besondere Anforderungen an die gesamte Wertschöpfungskette Holz. Das logistische Teilprojekt OPERA, das von der TFH Wildau geleitet wird, zielt auf eine Optimierung der Transportkette Schwachholz ab. Schwerpunkte sind die Ortung und Navigation im Wald mit Hilfe der RFID-Technologie, die Transportorganisation und die Optimierung der Informationsflüsse.

Dipl.-Forstw. M. Schultze |

Copyright © 2005 LogForum, Wy¿sza Szko³a Logistyki, ul.E.Estkowskiego 6, tel. 061 852 95 55, 851 06 04, tel./fax. 061 851 06 03 |