|

|

|

REAL-TIME-SIMULATION OF A LOGISTIC-SYSTEM INCLUDING DRIVES AND SENSORS FOR TESTING PLC-SOFTWARE BY SOFTWARE Wilhelm Caninenberg ABSTRACT While installation of warehouse-managing-systems, storage- and transport-systems and their PLC problems and errors are caused by untested software. Repairing the defects causes delay of time and stress with deadlines. Insufficient tests of PLC-Software cause nearly 40% failed systems. More complicated functions in storage- and transport-systems demand a linking of hundreds of drives and sensors. Furthermore PLC-Software is installed after hardware as the last step of installation of a logistic-system. The refore PLC-Software is getting the responsibility of failure and delaying.

Testing PLC-Software before real-operation avoids those defects and problems. The company Swisslog AG, Switzerland asked us to develop a real-time Simulation System called E-Control. E-Control is such a testing system. It shows the whole of an operating Logistic-System on a PC including all drives and sensors. Inspection of the PLC-Software takes place by watching the events and the movement of objects on the monitor of the PC without the construction of the real Logistic-System. The Simulation considered a high degree of details in pictures and movement as well as the capture of the positions of the objects (containers or pallets). INTRODUCTION Simulation is one of the most important tools for planning and realization of logistic systems. Of course there are different demands on simulation systems. For example you want to know the performance, the capacity or the time running through of a future system you can use suitable simulation systems. In a next step using another simulation you get information about the performance of single machines such as storage machines, rotating tables or distributing vehicles. In this step of planning a logistic system you can improve performance of the entire system by changing the number, the grouping and the selecting of these machines.

Fig. 1. Participating layers

Rys. 1. Struktura warstw For testing the coupling there are simulation systems required which shows all structures of the communication. After using these systems the exchange of messages is checked and the correctness of communication is reached.

Fig. 2. Software-testing concept

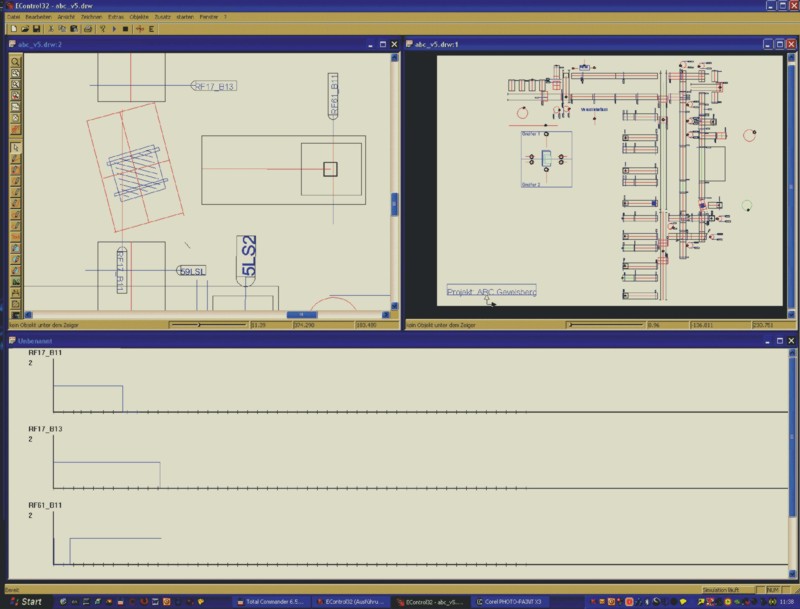

Rys. 2. Koncepcja programu testującego CONCEPT OF REALTIME-SIMULATION In contrast to the systems mentioned before this simulation system which I am talking about is developed for real logistic systems including drives and sensors in real time. In most cases the control-layer is realized by PLC for example Siemens S7, but this is not a condition. The exchange of the drives- and sensor-signals between the animation on PC and a PLC in real time is the core of this system. Real time means that the signals appear in the same sequence of time as in the later installation. This is an important advantage of this simulation system which got the product name E-Control. The refore E-Control got an interface in form of original PLC-input and -output. The core of E-Control is the exact simulation of movements of the containers and pallets through the transport system. With E-Control the real system is replaced by a virtual one on the PC. The PLC is connected with the virtual facility. The import of the virtual facility is based on technical drawings in form of CAD-data, which were accepted by a CAD-core of E-Control. In these the elements for simulation are entered true to scale. A simple configuration is shown in Fig. 3.

Fig. 3. Simple example of conveyor

Rys. 3. Prosty przykład przenośnika Beside of the movement of the standard logistic machines E-Control does simulate the movement of the containers or pallets as a reaction of the signals of the connected PLC. The refore the following data are required:

Because of the exact details of movements and events in the visual system on the screen of the PC E-Control is able to exchange the signals with a connected PLC in real time. The objects containers or pallets are animated and are moving through the visual system. Each object can get an individual identification or number, which scanners or RFID-readers can read. RUNNING A SIMULATION Fig. 4 shows an example of a configuration of a simulation system. Usually one PC is sufficient. However whether one PC or more they are connected (as in the real system later on) by bus such as Profibus, Interbus, Industrial Ethernet and so on. To describe running a simulation we assume all CAD-data about the hardware of the designed logistic system is stored.

Fig. 4. E-control simulation system (exemplary configuration)

Rys. 4. System symulacyjny kontroli elektronicznej (przykładowa konfiguracja) In a first step courses or segments are to specify where the containers or pallets have to run through. The se elements get drives. Parameters of a drive are speed, changing the speed, signal to switch on the drive and so on. Beside drives sensors are to be placed. Beside the position sensors are represented by light-barriers. Sensors get the parameters kind of signal (high or low), line of operation and the number of signal which the PLC will get later on. All parameters are stored into variables you get to know by usual programming languages. The advantage of using variables is demonstrate later on. Up to here you have integrated all relevant elements for a simulation such as crossing points, rotary desks, distributing vehicles and so on. So far we suppose there is no PLC until yet. The n you can program the conditions of movements, the logic of controlling and the order of events. You can reproduce the controlling-software by script-languages such as Visual-Basic-script or Java-script (Fig. 5: stand-alone-mode). But this is not the main goal of E-Control. The main purpose for developing E-Control is testing PLC-Software by a virtual Logistic system on PC. The script-programs are running in background of visual simulation in cooperation with variables I mentioned before. The refore in the next step (Fig. 5 develop-mode) the PLC is connected with the simulating PC. In this step the controlling-software is developed on PLC online. The correctness and functioning of the PLC-software is tested by the virtual system on PC. As I said before virtual system and PLC exchange signals in original PLC-kind and in real time.

Fig. 5. Kinds of modes

Rys. 5. Rodzaje modeli In the last step the developed PLC-software is tested without the script background programs as a whole. FUNCTIONS OF E-CONTROL Beside of the possibility integrating CAD-data E-Control is marked profitable because of:

Especially the integration of a list of variables, which represent the state of system and the order of events of the simulation allows high flexibility and wide application. The list of variables (Fig. 7) is used by several trends and changed by the following:

So several scenarios of simulation can use the list of variables:

Fig. 6. E-control functions

Rys. 6. Funkcje E-kontroli

Fig. 7. Integration of variables and script functions

Rys. 7. Integracja zmiennych i funckji skryptowych CONCLUSION Using such sources of help for testing software there is to discuss expenditure and advantage. Beside of investment for hardware and software costs for preparing the simulation model and for doing the tests are to consider. Compared with this essential advantages are to mention:

The refore E-Control is very useful in education of our students in programming PLC-software. ACKNOWLEDGMENT The author would like to thank company Swisslog AG, Switzerland for their support during developing E-Control, Herrn Dr.-Ing. Volker Heidenblut for many comments and advices, Herrn Dipl.-Ing. Andreas Koch who hat a great part in planning the concepts and structures and in coordinating the programming tasks. REFERENCES

SYMULACJA W CZASIE RZECZYWISTYM SYSTEMU LOGISTYCZNEGO OBEJMUJĄCA NAPĘDY I SENSORY DO TESTOWANIA OPROGRAMOWANIA STEROWNIKÓW LOGICZNYCH PRZEZ PROGRAM KOMPUTEROWY

STRESZCZENIE W trakcie instalacji oprogramowania systemu zarządzania magazynami i transportem można napotkać problemy ze sterownikami logicznymi oraz błędy spowodowane przez nieprzetestowane oprogramowanie. Usuwanie napotkanych błędów powoduje opóźnienie pracy i niemożność dotrzymania ustalonego wcześniej harmonogramu wdrożenia. Niewystarczająco przetestowane oprogramowanie sterowników może być powodem nawet 40% przypadków niefunkcjonowania systemu. Bardziej zaawansowane funkcje w systemach magazynowych i transportowych opierają się na współpracy i połączeniu setek napędów i sensorów. Oprogramowanie sterowników logicznych jest instalowane po podłączeniu całego sprzętu, jako ostatni etap instalacji systemu logistycznego. Z tego też powodu to właśnie ta część systemu w postaci oprogramowania sterowników jest obarczana często winą za opóźnienia i komplikacje przy wdrożeniu. ECHTZEIT-SIMULATION VON LOGISTISCHEN SYSTEMEN EINSCHLIEßLICH ANTRIEBEN UND SENSOREN ZUM TESTEN VON SPS-SOFTWARE MIT SOFTWARE

ZUSAMMENFASSUNG. Während der Inbetriebnahme von Warenverteilanlagen, Lager- und Transportsystemen und den zugehörigen Steuerungen entstehen Probleme und Fehler durch nicht getestete Software. Durch die Reparatur der Fehler entstehen Zeitverschiebungen und Probleme mit dem Fertigstellungstermin. An unzureichenden Tests der SPS-Software scheitern fast 40% der Software Installationen. Da Materialflusssysteme mit zunehmender Vielfältigkeit der Aufgaben immer komplexer werden sind hunderte von Antrieben und Sensoren anzuschließen. Da die Software nach der Hardware als letztes Glied in der Installationskette steht wird ihr zwangsläufig eine fehlgeschlagene Inbetriebnahme verantwortlich zugeschoben.

Wilhelm Caninenberg |

Copyright © 2005 LogForum, Wyższa Szkoła Logistyki, ul.E.Estkowskiego 6, tel. 061 852 95 55, 851 06 04, tel./fax. 061 851 06 03 |