|

|

|

AIRPORT LOGISTICS: INNOVATIVE SOLUTIONS FOR BAGGAGE-HANDLING Bernd Hentschel ABSTRACT Airport logistics is a very complex and new field of logistics. There are some new approaches to deal with this topic. This article will show some already existing solutions in baggage-handling. We will also provide an outlook for the future of airport logistics. The key to solve this issue is to concentrate on new concepts for controlled goodflows and to increase the automatisation of the transport of the luggage. Today there is a huge gap between the existing results and the future demand.

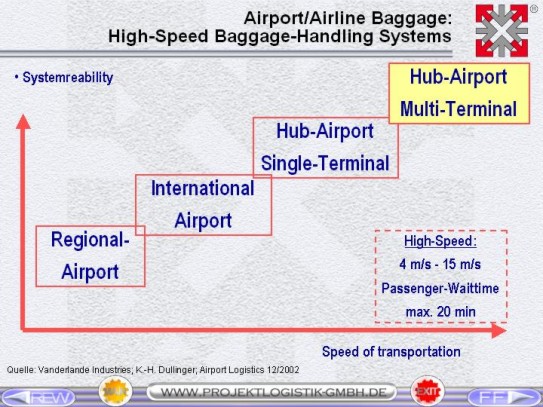

INTRODUCTION Currently, in the field of logistics, there are different developments in the area of airport-logistics. This is not strange because the branch of air-transportation with increasing numbers of passengers and also increasing cargo demands new logistics solutions. Especially due to the new developments in the field of large-capacity aircrafts by BOEING and AIRBUS with more than 500 passengers, there is a need for totally new navigation and controlling concepts for the flow of passengers and baggage. The Turn-Over-times for airplanes will decrease significantly and this will strengthen the position of new concepts for controlling logistics processes. Therefore research and education in this area is an open field. The following paper shall give you an outlook of new developments in baggage-handling and also some solutions in this matter. REQUIREMENTS OF THE AIRPORT DEVELOPMENT Due to the increasing size of airplanes und the increasing number of passengers, the handling of baggage will be more and more important. In-time delivery will have a very high priority for the passenger. With the increasing size of an airport also the requirements and complexity of reliable baggage-handling will increase. We can define four different types of airports, as you can see in Figure 1. Essential for the development are international airports and HUB terminal with high demands for the baggage-systems and the speed of transportation.

You can assume today, that future material flow and the speed of transport in the area of baggage will increase from currently 4 m/s to 15 m/s. These results are caused by higher numbers of passengers for each airplane and faster baggage-handling to accomplish shorter queues by the distribution of the baggage. This new speed of transportation demands new flow of material and transport container. The leader in this particular sector of transport systems is the Dutch company VanderLande Industries, witch already provides revolutionary and proven solutions. The concept of DCV with traversing transport containers, witch can tip over in the same time, is one of them. A transport speed up to a maximum of 15 m/s and a loading capacity of 5000 pieces per hour on the main lines of material flow will ensure this. The frequency of loading with luggage is currently reported with 1800 pieces an hour and shows a bottleneck. Especially the loading of the baggage on the interface of airport and airfield and therefore the loading of the airplane is one of the still unsolved problems. Figure 2 presents one baggage transport solution from VanderLande Industries as DCV concept. Particular this is the BAGTRAX-System ® as part of a whole system solution. You can see clearly the transport containers. They are rail guided and powered by a linear motor. It is also possible to realize diagonally transports by tipping over the transport container.

The solution for diagonally transport by tipping over will be shown by the following Figure from VanderLande Industries. This is an example from the airport of Paris Charles de Gaulle (Paris CDG).

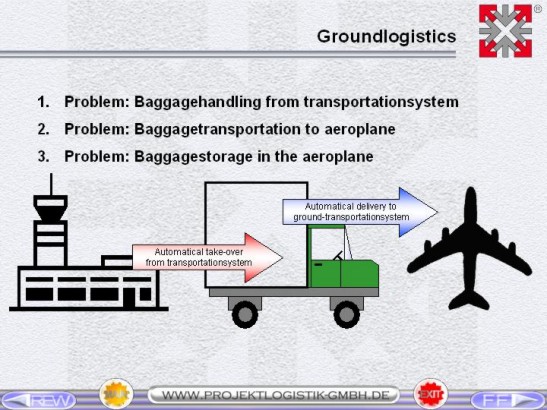

You can see that baggage-handling is quite advanced in the technical development. Likewise, it is possible to deal with the high demands of material flow in airports. In the following airfield process, the stand-by of the luggage from the airport to the airplane, there are significant gaps in the development. What does the logistics request looks like? LOGISTICS REQUIREMENTS FOR THE LUGGAGE TRANSPORT We can define the requirements for luggage transport in the following years like this: we have to differ between low-cost-carries and traditional airlines. The demand for the turn-over-times, the times between landing and take off, are cut for the low-cost-carrier. In Berlin-Schönefeld a turn-over-time of 30 min. is quite normal. But the demand for the future will be 20 min! This is an enormous challenge for the transport and its optimizing of the material flow. Today we have on major airports a baggage transfer performed by personnel of the ground-service provider with 16 to 18 t in 8 h. A huge mass for transfer and also a high frequency of transfer. Here it is necessary to start with the development of the logistic. Let's assume large-capacity aircrafts with about 500 passengers, regular airlines will not have to cut their turn-over-times but there is no doubt that something has to be done to speed up the process of transferring the baggage. Therefore the target is: to optimize logistically the whole process of transferring the luggage. Especially the baggage-handling with the fastest way of providing the passenger with his luggage 20 min after landing. We deal in fact with three problems in the logistics process. Figure 4 shows these relations.

Different Developers of baggage-handling are dealing with this question. Major impacts are seen in the area of "handing-over of the luggage from the conveyor belt to the transport vehicle" from the German companies ONERO Grenzebach GmbH and LÖDIGE Industries GmbH. Both companies already have a great achievements in the development of baggage-handling for many years. What are these developments? A solution, invented by LÖDIGE Industries GmbH is seen in Figure 5.

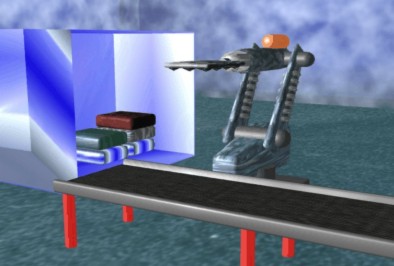

It is known as LÖDIGE ALPHA-Packer and is connected to a angle-arm-robot solution. It is possible to serve the currently used transport units and, with an intelligent variant, to serve even the Unit Loading Devices (ULD-Container). Hereby the geometry of the container will be scanned and information about free space will be transferred to the robot. After this the loading of the ULD can start. You can see a highly developed solution of the company ONERO Airport Logistics respectively ONERO Grenzebach GmbH (current name) in Figure 6. It is already in use at the airport of Zurich (Swiss). Application at the airport of Amsterdam is being considered. You can see the rail guided robotic solution during the phase of loading an ULD. Even here we have the same principles of 3D-packaging, controlled by data transfer, robotic packaging and automatic recognizing of the luggage. It is extremely hard to deal with the techniques of grabbing the different type's baggage. We all know the different geometries of the luggage, which is to been grasped. It is a huge number of special shapes. Starting with hard-case suitcases to damageable soft-cases and last but not least soft sport bags - everything has to be managed by the robot in the shortest possible time. ONERO Grenebach GmbH is using a grabbing device with a continuous band. So it is possible to lay down the luggage automatically and as well as to transfer the luggage independently on a transfer platform. The device is shown in Figure 7.

The disadvantage of the ONERO-grasp-technique has caused different logistics service providers to start also to deal with this special element of construction. In cooperation with VanderLande Industries and other partners, the company Projektlogistik GmbH has developed a new concept of grabbing and loading. You can see it in the internet by visiting the site www.projektlogistik-gmbh.de. You will find it in the category of "airport logistics". The principles of functioning are presented. It is already prepared to be registered as a patent. The concept is shown in Figure 8.

Different handling systems were examined by a morphological elaboration. In the end the demands of the different shapes of luggage were very complex and difficult. A solution with a telescope arm for the transfer was the optimal result to transfer and load the baggage into the ULD's. Currently all partners prepare in cooperation a final concept to put this solution into action. CONCLUSIONS From a current point of view airport logistics is a highly innovative area for logistics service providers and developers. With increasing numbers of passengers and also an increasing size of airplanes, the problem of baggage-handling will be a central concern. It is wise to start the development of adequate logistics solutions right now. This article gave you an outlook of current development and already used solutions for baggage-handling. One can assume that in the next five years this problem will be solved in an economical and technical manner that is satisfactory. REFERENCES Bien, M., Franke, B., 2004, Automatisches Gepäckhandling - Anforderungen an die Beladung von Gepäckeinheiten. VDI - Bericht 1861. Halbmeyer, H., 2004, Die Systemplattform der Gepäckförderanlagen des Flughafens München am Terminalv2. VDI - Bericht 1861. Hammerstädt, W., 2004, Das Betreibermodell und die Steuerung eines der größten Hubs in Europa Flughafen München GmbH/ Deutsche Lufthansa AG - Betreibermodell und Hubcontrolling des Terminals 2. VDI - Bericht 1861. Jansen, R., Schelhove, G., 1999, Intelligente Kennzeichnung am Beispiel der Fluggepäckabfertigung. PackReport, 32, 4. Koini, M., 2004, Automatisches Gepäckhandling - Technische Lösungen. VDI - Bericht 1861. INNOWACYJNE ROZWIĄZANIA LOGISTYCZNE DLA OBSŁUGI BAGAŻU NA LOTNISKACH

STRESZCZENIE

Logistyka lotnicza to bardzo złożony i zupełnie nowy obszar logistyki. Pojawiło się kilka nowych podejść do tego tematu. Niniejszy artykuł pokaże kilka funkcjonujących już rozwiązań w obsłudze bagażowej. Przedstawimy również perspektywy przyszłych rozwiązań w branży logistyki lotniczej. Kluczem do rozwiązania problemów, pojawiających się w tym temacie, jest skoncentrowanie się na nowych koncepcjach kontrolowanego przepływu dóbr i zwiększenie automatyzacji transportu bagażu. Dzisiaj istnieje duża luka pomiędzy obecnym stanem rzeczy a wymaganiami w przyszłości.

FLUGHAFENLOGISTIK: NEUE LŐSUNGEN FÜR DAS BAGGAGE-HANDLING

ZUSAMMENFASSUNG.

Flughafenlogistik ist ein sehr komplexes und neues Feld der Logistik. Hier gibt es einige neue Ansätze zu diesem Thema. Dieser Beirtag zeigt bereits existierende Lösungen für das baggage-handling. Es wird auch ein Ausblick auf die Zukunft der Flughafenlogistik gegeben. Der Schlüssel, um das Problem zu lösen, ist die Konzentration auf neue Konzepte des Materialflusses und die Erhöhung der Automatisation des Gepäck-Transportes. Heute sehen wir eine riesige Differenz zwischen den existierenden Ergebnissen und dem Zukunftsbedarf.

Prof. Dr.-Ing. Habil. Bernd Hentschel |

Copyright © 2005 LogForum, Wyższa Szkoła Logistyki, ul.E.Estkowskiego 6, tel. 061 852 95 55, 851 06 04, tel./fax. 061 851 06 03 |